The UV light from LEDs is ordinarily in the scope of 365nm-385nm, it has an extreme focus and it’s exceptionally reliable, this considers exact and predictable curing. It likewise considers a more effective cycle as it can fix in a flash, contrasted with minutes or hours for other curing strategies. UV LED curing likewise doesn’t create heat, which can be valuable in specific applications where intensity can be an issue.

Comparison of UV LED curing and UV curing. What Characteristics Set Them Apart?

UV restoring regularly utilizes an UV light or mercury fume light to fix the materials, while UV LED curing utilizes UV light-transmitting diodes (LEDs) to fix the materials. UV LED curing can fix in a flash, while UV curing can require minutes or hours to fix. UV LED curing is more energy productive than UV restoring on the grounds that it utilizes less ability to create UV light.

UV LED curing involves light in the scope of 365nm-385nm, considering predictable curing. UV curing utilizes an expansive range of light that can differ contingent upon the kind of light utilized. UV LED curing is more harmless to the ecosystem than UV curing on the grounds that it doesn’t create destructive discharges.

Utilizations of UV LED curing in The Field of Microelectronics

In the field of microelectronics, UV-LED curing paste is generally utilized for holding and fixing microelectronic parts, like sensors, chips, and semiconductors. It is additionally utilized for the epitome of microelectronics parts and for PCB gathering.

UV glues, otherwise called UV-reparable cements or sealants, are a kind of cement that is enacted or restored through openness to bright (UV) light. These cements can be produced using a wide range of polymer saps, like acrylate or epoxy. When presented to UV light, the monomers in these pitches respond and polymerize, framing serious areas of strength for a.

UV sealants are not quite the same as conventional sealants, like epoxies and cyanoacrylates, which expect time to fix at room temperature or intensity to fix. UV pastes and sealants, notwithstanding, fix right away when presented to UV light, which makes them ideal for fast, robotized gathering processes.

Here are a few different ways UV LED curing is done through glues in the field of microelectronics.

Holding and fixing

UV LED curing paste is utilized to bond and seal microelectronic parts, giving a quick, proficient, and exact technique for holding and fixing. The UV light from the LEDs gives a speedy curing process that dispenses with the requirement for intensity and tension, which can harm touchy electronic parts. Thus, this gives us items that have an exceptionally slim likelihood of being flawed.

Exemplification

UV-LED curing paste is utilized to epitomize microelectronic parts to safeguard them from dampness, heat, and other ecological elements. The UV light from the LEDs gives a fast restoring process, and the seal made is impenetrable, giving durable security. With the assistance of UV LED curing not exclusively will the exemplification be of excellent yet will build the security of the end result.

UV-LED curing paste is utilized in the PCB (Printed Circuit Board) gathering process, where it is utilized to bond the different parts of a PCB together. Contrasted with conventional innovation like UV pastes and sealants, UV-LED curing paste is quick, proficient, and exact, and it assists with working on the exhibition and dependability of the PCB. Generally, UV LED curing sealants assist with building PCB sheets way better compared to what past items and contenders of UV LED curing offer.

Adhesive that Conducts

UV-LED curing paste can likewise be utilized as a conductive glue, which assists with disposing of the requirement for patching, which can harm the microelectronics parts. UV LED curing paste gives you a substitute to customary UV pastes and sealants. It is different on the grounds that here substrates never send in the frequency of the UV. Besides, what goes with them an excellent decision is because of their exceptional optical clearness.

Touch Screens

Makers of touchscreen gadgets frequently will generally use UV LED curing glue before get together. The most gainful part is the low intensity and on-request restoring that this substance offers through UV LED lights. It forestalls likely harm to delicate parts of a fairly valuable part of an electronic gadget by conveying an extremely steady and moment result.

Is it true that you are Additionally Inspired by UV Driven curing? We Have An Answer!

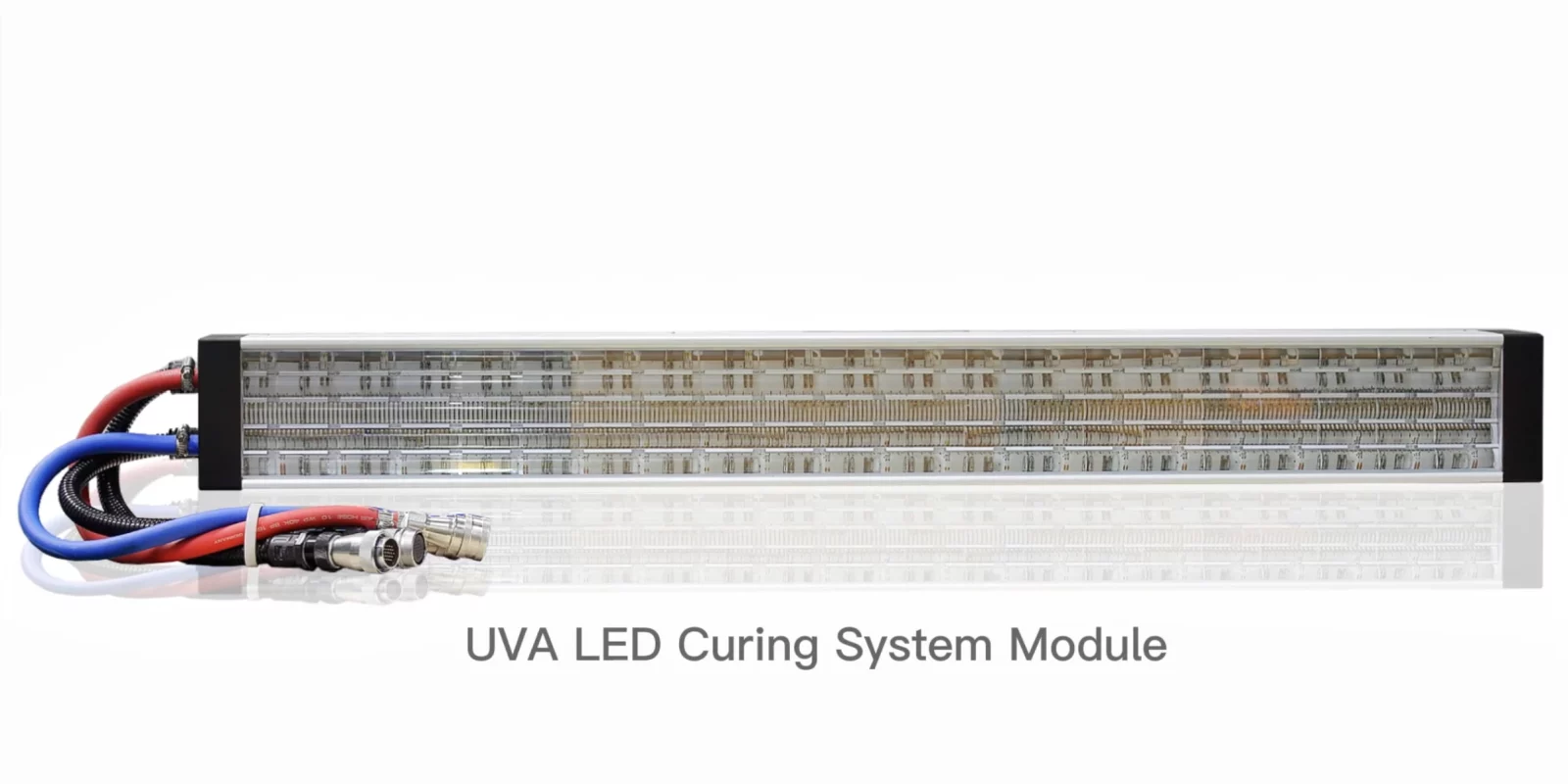

UV LED curing is a developing area with a ton of possibilities. In the event that you are additionally who has begun to acquire interest in the field of UV LED curing and might want to investigate it for yourself, we have the ideal UV LED answer for you; we have the right aide for you.

Tiahui is one of the main UV LED producers that has a large number of choices to browse. Whether you are in the clinical business or the rural area, Tianhui has the right item for you. Going from UV LED diode to UV LED module, we have whatever is at the forefront of your thoughts. In the event that you need quality with esteem, Tianui is the situation.

Wrapping It Up

UV LED curing innovation is totally progressive. With this, a lot more prospects have opened up. When contrasted with conventional advances like UV curing, UV LED curing offers upgraded execution and is exceptionally practical too.

We trust this article was useful in finding the response to your inquiries in regards to the utilization of UV LED curing in microelectronics. Remember to look at Tianhui for the best UV LED items.

The advantages of using UV LED mosquito traps to clean the air.

UV LED mosquito traps provide the added benefit of disinfecting the air in addition to capturing mosquitoes and other flying insects. These devices’ UV-C radiation can destroy a range of pathogens, such as viruses, bacteria, and mold spores, that may be in the air. These bacteria can bring on disorders like asthma as well as ailments like the flu, colds, and allergies.

UV LED mosquito trap is a safe and environmentally friendly alternative for air disinfection because they don’t require any chemicals. UV LED mosquito traps are a safe and efficient way to reduce the amount of germs in the air without using chemical-based insect repellents or air fresheners.